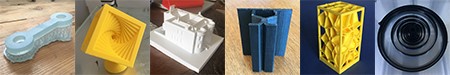

3D Kernow March Update – recent developments in 3D Printing capabilities.

For commercial customers, we have added the ability to print in sturdier materials, by adding options to print in Nylon or Resins, on top of PLA, which is our workhorse starch-based thermoplastic, optimised to deliver high-quality surface finishes. To give you an idea of the toughness we can deliver, a resin test item recently withstood 210 kilos before snapping.

We continue to print for a wide variety of clients

- Prototype containers for chronometers aimed at the yachting market.

- A scanned child’s jawbone (in resin) for a dental technician

- A seven part valve for someone in the surfing community

- A medal for casting on behalf of a Falmouth-based company

- Skirting board ends for a do-it-yourself home builder

- An experimental mould for chocolate bars

- model railway components involving features below 1 millimetre (the thickness of a credit card)

- A near metre-long replica of a balustrade from a historic house in Camborne

- A 40 hour print of another historic dwelling, Grove Hill House in Falmouth

- A set of feet for a settee to replace those lost by some removal men

- And a resin butterfly clip

The big challenge for this coming year is to get a better sense of how to deliver structural integrity as the items we print increasingly need to be used in real-life situations. For instance, items printed vertically may be much more fragile than when printed horizontally. We are thus working with the Marine-I project to get a better sense of how to optimise printing techniques and the choice of materials, with the goal of producing prints which will better stand up to the demands of factories and water-fronts. This work is being carried out by a researcher at Exeter University.

As part of our social goals, we continue to spread the word about 3D printing and design. This has recently involved

- Talking to Engineering and Design/Technology classes (Falmouth School)

- Demonstrating in careers days in schools and colleges (about once every ten days at this time of the year)

- Helping with STEM days

- Introducing would-be apprentices to the potential of 3D Printing and Design (with a particular emphasis on Autodesk’s Fusion 360)

I look forward to hearing from you.

———————————————————————————————————-

Louis Turner, 3D Kernow CIC, Falmouth:

- 0790 5204 677

- 3dkernow.org